Plasma and TIG processes. Automatic welding applications

Plasma and TIG processes used in automatic applications

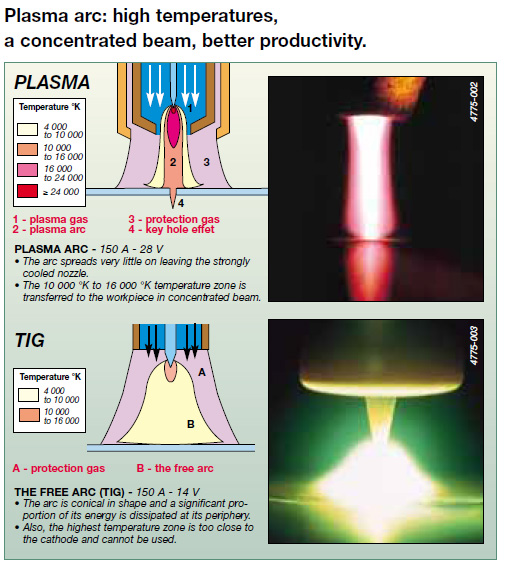

The plasma arc: a natural phenomenon tamed by Air Liquide Welding. The term plasma applies to gases at temperatures exceeding 3000 °C at atmospheric pressure. On the temperature scale, it can be regarded as the fourth state of matter after the solid, liquid and gaseous states.

The plasma is made up of excited ions, electrons, atoms or molecules; it occurs in nature, generated by lightning, for example. Since about 1960, and largely due to Air Liquide Welding, the word plasma has gained a new meaning, referring to the high-energy state caused by constricting an electrical arc by means of a diaphragm or nozzle.

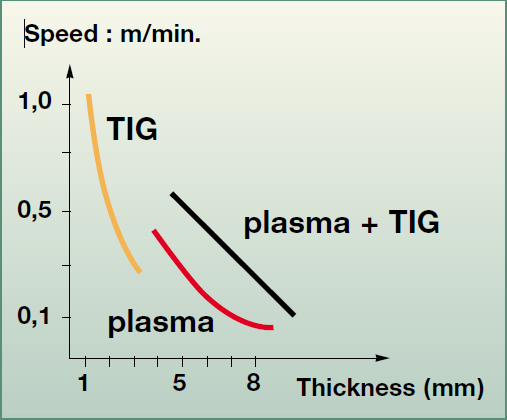

Plasma + TIG welding process

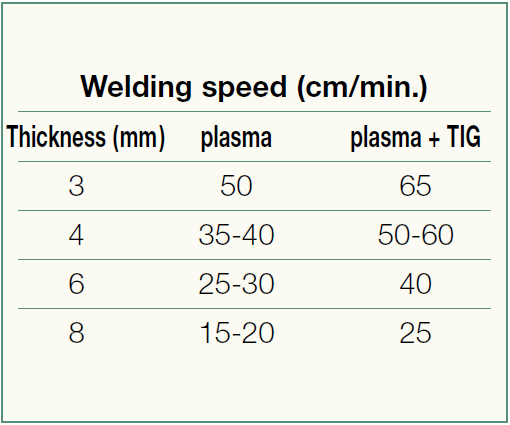

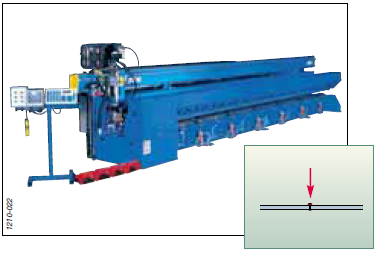

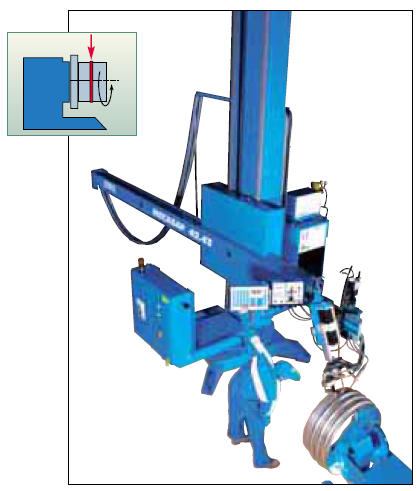

When the length of the panels to be assembled reaches 3 to 4 meters, a boiler-making or tube fabrication workshop

using a discontinuous forming process (rolling mill or press) can be restricted by the welding speed obtained with a single-torch plasma process.

Air Liquide Welding, an innovative specialist in TIG and plasma processes, has been able to integrate the two processes into a single installation which can improve productivity by 30 to 50 %.

Aluminium welding using the automaticTIG process 5 DC TIG

Plasma welding in the workshop

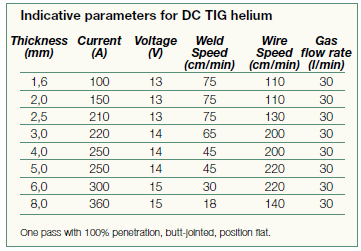

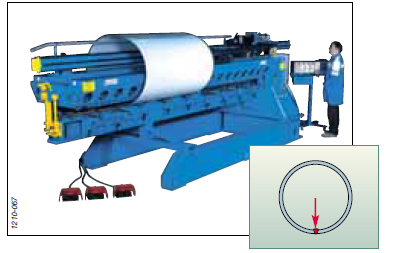

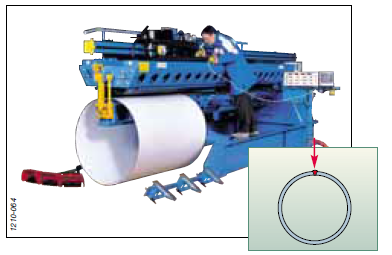

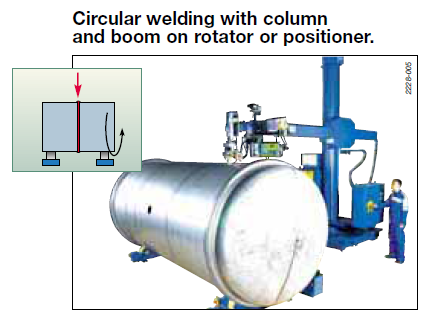

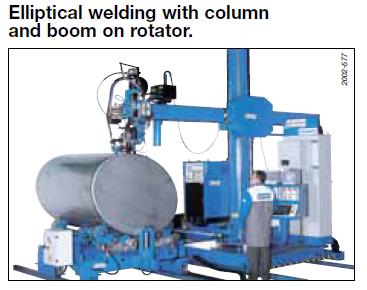

Vertical boiler work

Use of plasma or TIG processes for horizontal welding of stainless steel, noble metals, steels or aluminium. Manufacture of storage equipment for agriculture/food processing, petrochemical industries etc…

Turntable capacities: 5T, 10T and 15T. For other requirements please do not hesitate to contact us.

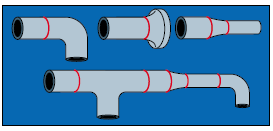

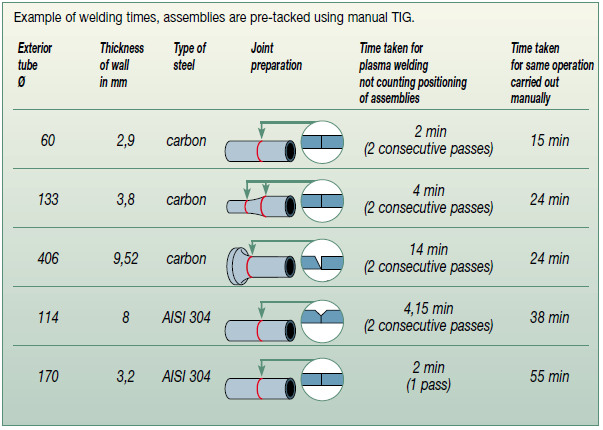

Plasma welding for prefabricated pipe work

Prefabrication of pipe work is carried out upstream of installation. It enables sub-assemblies to be prepared and welded from basic components (pipes, flanges, elbows etc…) in the workshop. It is used in a variety of industrial sectors:

- shipbuilding and off-shore platforms,

- refineries and power stations,

- chemical and agriculture/food processing plants,

- gas expansion and distribution

stations etc.

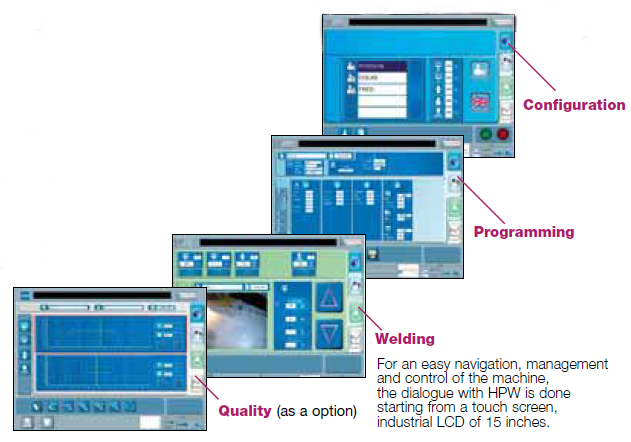

NERTAMATIC 450

NERTAMATIC 450 HPW

This installation meets the highest quality standards for welding and productivity for industries as diverse as boiler-making using stainless steels, aeronautics using noble metals, chemical engineering, energy production, transformation and transport as well as prefabrication of gas and petrol pipelines etc.

NERTAMATIC 450 plasma + TIG bicathode installation

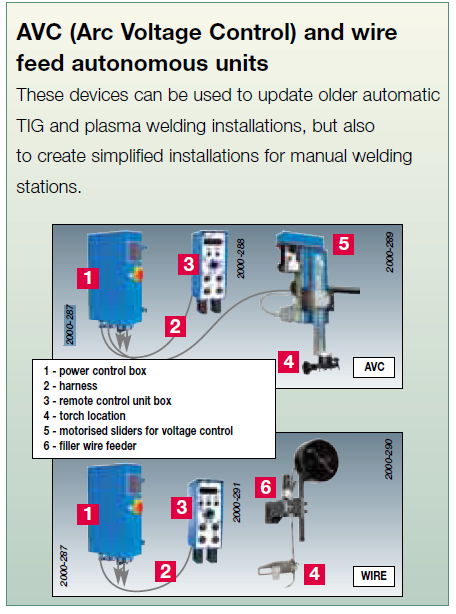

Add-ons

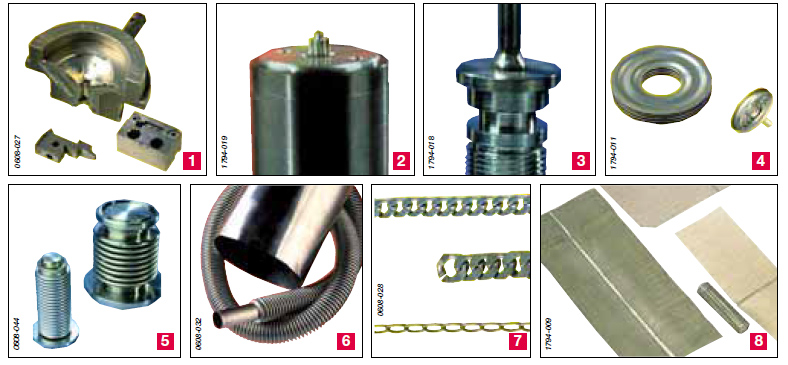

Microplasma

The microplasma process is used for welding fine thicknesses of the noble metals such as stainless steel, inconel, titanium, zirconium, alloys of silver and gold etc. For the electric and electronics components industries, small containers, metal filters and tool repairs as well as sectors of the horology, silversmith and medical industries.

1 – Mould repairs

2 – Motors and transformers

3 – Probes

4 – Measuring instruments

5 – Decompensator bellows

6 – Fine sheet metalwork

7 – Jewellery

8 – Filters

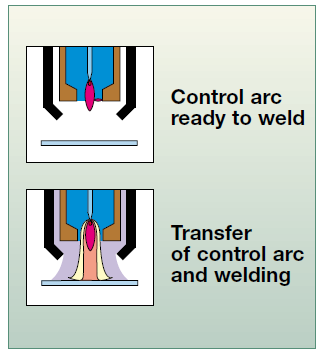

Deconfined plasma

The SP150 torch is specially built for automatic welding using the deconfined plasma process. It is used for intensive production and is suitable for all machine types. The most recent applications are the production of melt-runs, small weld beads or very repetitive welding.

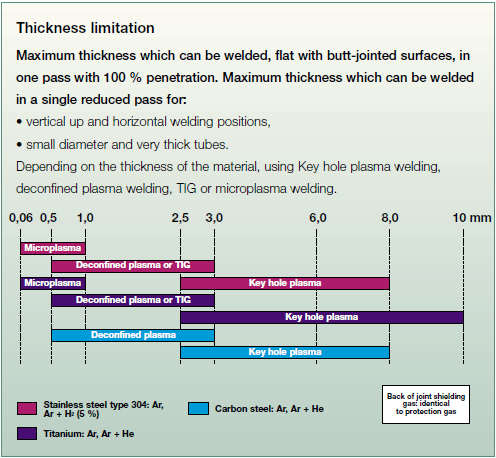

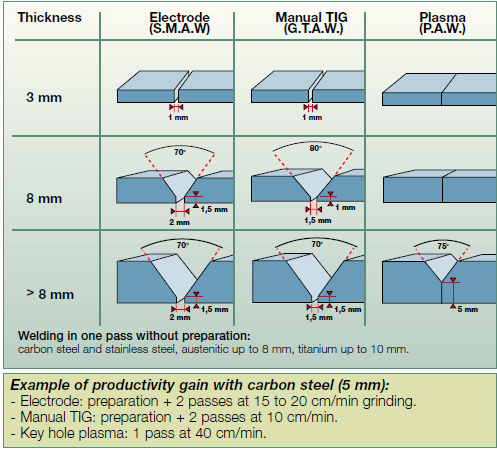

The installation can also use the control arc double-flux TIG process using smooth or pulsed current. Plasma is an evolution of the TIG process which brings many opportunities for increasing your productivity.